The Green Beam advantage for line lasers….

For the first 30 years of laser level production all laser diodes were red due to the prevalence of this technology for computer devices , Bluetooth connectivity and automotive electronics.

With laser levels being of a rotating nature and requiring an aligned frequency detector it was immaterial that the red beam couldn’t be seen by the human eye over a relatively short distance, because the detector could pick up the laser beam and combine with sound to show the user the level.

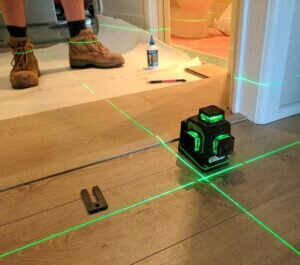

With the advent of line lasers in the last 15 years and the inherit limitations of being able to project a red beam at distance, the later technology green beam laser diodes have become the colour of choice for many line laser applications.

The reason is that the human eye sees green beam 4 times better than red, so the projected line of a green beam gives an illusion of being brighter and can be seen over a longer distance.

For any short distance indoor applications less than 10m there is no noticeable difference between the brightness of a red and green beam and for many tasks a red beam will suffice. On longer distances including commercial work a green beam comes into its own and can be used without a detector up to 20-25m dependent on surrounding light.

Red diodes are cheaper to produce, given their many applications in other industries so on average a red beam laser is still 10-20% less expensive to purchase than an equivalent green beam model.

iMEX, being a specialist laser level brand has a choice of red beam or green beam equivalents in most of the model line-up and the new Series 11 line and line/dot lasers that are being released now have enhanced line visibility, brightness and definition in both red and green models.